‘We are all quick and pragmatic’

Cognitive robotics is not just about performing tasks, it is also the art of improving work processes. So this year’s Minor Robotics was graced by a process innovation: TU Delft students teamed up with students from ROC Mondriaan, a school for vocational training. How did they fare?

Creating a robot from scratch in less than five months. This is the unique challenge offered by the TU Delft robotics minor. It attracts some of the most ambitious academic students, who form multidisciplinary teams and connect intensely with each other and their project clients as they design and build a robotic prototype. Including practically trained vocational students from ROC Mondriaan was a natural step to enhance the programme. The new collaboration started, naturally, with fits and starts.

Most primary school classes are a kaleidoscopic mix of talents. But at the age of twelve, the practically talented and the theoretically inclined start to go separate ways. Under the Dutch school system, mathematics wizkids have few opportunities to rub shoulders with peers who are gifted in the areas of actual making, building and repairing. It is only after their education ends that these two groups meet again, as engineers and mechanics and operators in the workplace. TU Delft and ROC Mondriaan wanted to see if they could somehow change this pattern.

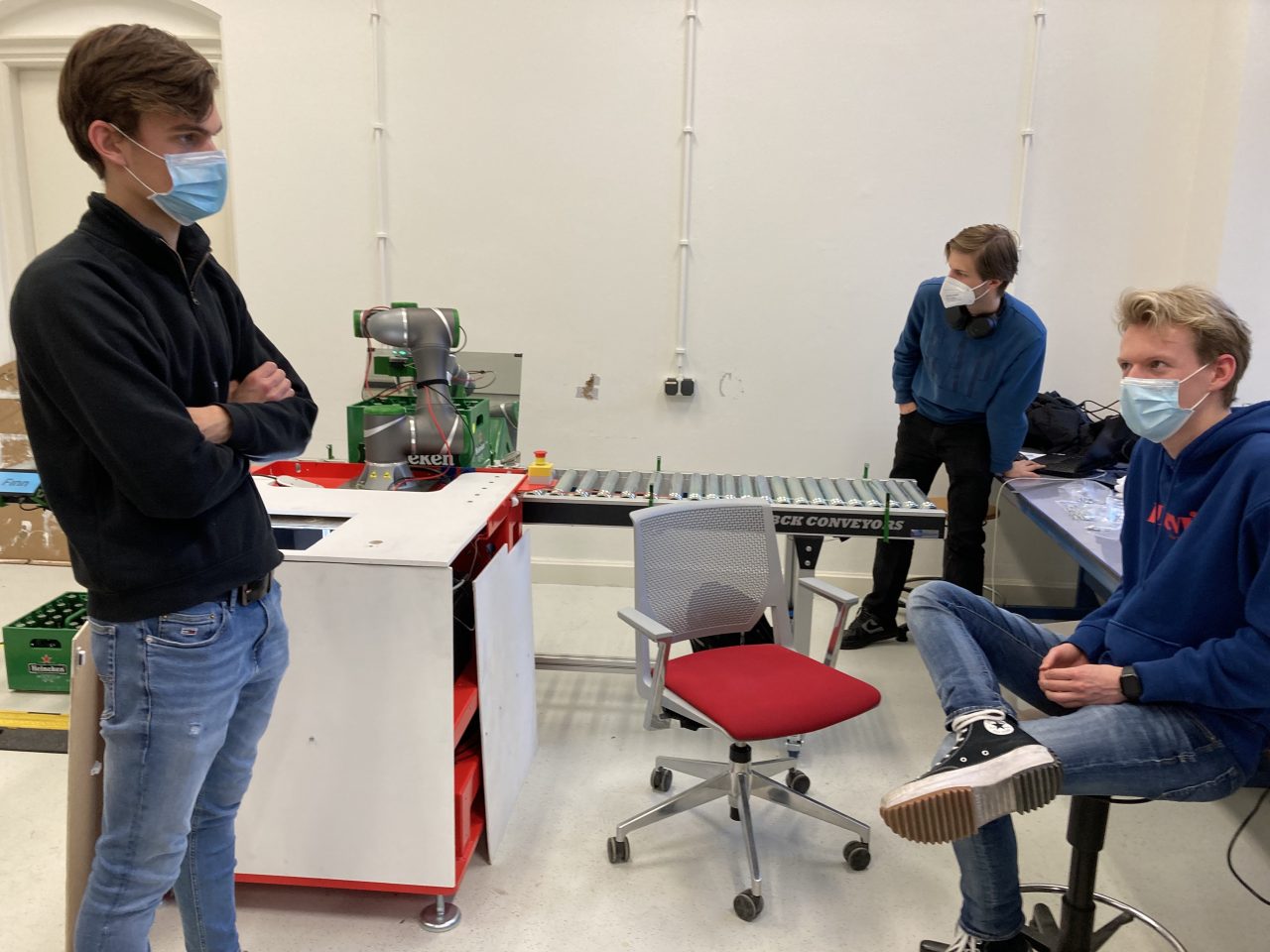

So a small experiment began. In the new EDUCATE wing in RoboHouse, which offers ample space for student teams, the Robotics Minor 2022 got practical support with prototype building from ROC Mondriaan students. We asked two robotics students about their experience.

“I remember them drilling some holes in a table for us,” says Robert van Dijk, the computer science specialist of team B.I.E.R. that built a collaborative quality control robot for Heineken. “Towards the end of the project there were quite a few practical jobs to be done. But I found it hard to concentrate on my own work. Every five minutes they [Mondriaan students Thomas, Marien and Tom] were asking me another question. This was costing us too much time, in my opinion. But I agree that this set-up has potential. It makes sense to have extra hands on the job.”

More clarity about the kinds of things we can ask them to help with. Floris van Mourik, electrical engineer of team PRISTINE

“We are all quick and pragmatic in our team, and the ROC students were also quick and to the point,” says Floris van Mourik, electrical engineer of team PRISTINE. “I’m a fan of rapid prototyping, and we all started with a lot of enthusiasm and ideas. There was a big burst of energy at first, then we calmed down a bit and had time to make some changes to our design. We gave technical requirements to the Mondriaan students, and they executed well. But it was also a bit abrupt. Without a clear beginning or ending. Maybe in the future there can be more clarity about the kinds of things we can ask them to help with.”